Yalin Liu, Associate Researcher. She obtained her undergraduate and master's degrees in Civil Engineering from Ocean University of China, and her Ph.D. from Auburn University in the United States. She also completed her postdoctoral research at Tsinghua University. Her research directions mainly include: High performance cement concrete pavement design; Microstructural characterization of cement-based materials and multi-scale analysis; Finite element modeling of concrete structures; Properties of ultra-high performance concrete (UHPC); Time dependent behavior (shrinkage and creep) of cementitious materials.

Project1: 2025.01-2028.12, The Key Programs of National Natural Science Foundation of China, Theory and Method of Long-Life Design of Heavy-Load Cement Concrete Pavement in Extreme Environment, responsible for fund of 400,000 RMB, Participation.

Project2: 2025.01-2029.12, The National Key Research and Development Program of China, Multi-Stage Emergency and Multi-Level Toughness Improvement Technology and Verification for Slab Instructure, responsible for fund of 300,000 RMB, Participation.

Project3: 2024.01-2026.12, The National Natural Science Foundation of China for Young Scholars, Creep Properties and Creep Mechanism of Internally-Cured UHPC with High-Strength Porous Aggregate Applied to Large-Span Structures, total fund 300,000 RMB, PI.

Project4: 2019.11-2021.10, The China Postdoctoral Science Foundation, General Program, Research on Abrasion Resistance and Shrinkage Performance of Long-Life UHPC Pavement, total fund 80,000 RMB, PI.

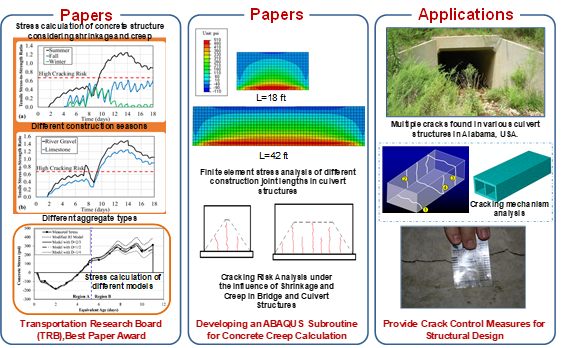

1. Research on Creep Theory and Structural Numerical Modeling of Conventional Concrete and Lightweight Aggregate Concrete: The finite element method was employed to conduct computational analyses on the early-age stress development in concrete under varying water-to-binder ratios, aggregate types, and mineral admixture effects. The shrinkage and creep model (B3 Model) was modified to develop predictive models suitable for early-age concrete. By adopting a 3D numerical calculation method for stress increments and strain increments, the shrinkage and creep models were implemented into FE subroutines to perform stress calculations and cracking risk analysis of concrete structures.

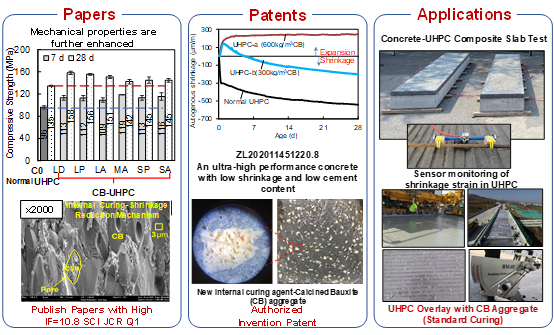

2. Developed a New Low-Shrinkage UHPC Material: Calcined Bauxite (CB) aggregates were employed as internal curing agent to prepare non-steam cured, low-shrinkage, high-abrasion-resistant UHPC for pavement applications. Compared with conventional UHPC, the developed UHPC-CB achieved over 50% reduction in autogenous shrinkage and up to 17.5% improvement in compressive strength, while demonstrating more than threefold enhancement in abrasion resistance compared to ordinary concrete. This innovation effectively resolves the technical challenge of mutual constraints between conventional shrinkage-reducing materials and mechanical/skid-resistant properties. The research outcomes have been successfully applied in UHPC overlay of a concrete bridge in Yunnan Province.

1. Liu Y, Li C, Wei Y, et al. A state-of-the-art review of research on the use of calcined bauxite aggregate in civil engineering[J]. Case Studies in Construction Materials, 2025: e04188.

2. Liu Y, Wang L, Wei Y, et al. Current research status of UHPC creep properties and the corresponding applications–A review[J]. Construction and Building Materials, 2024, 416: 135120.

3. Liu Y, Wei Y, Ma L, et al. Restrained shrinkage behavior of internally-cured UHPC using calcined bauxite aggregate in the ring test and UHPC-concrete composite slab[J]. Cement and Concrete Composites, 2022, 134: 104805.

4. Liu Y, Wei Y. Effect of calcined bauxite powder or aggregate on the shrinkage properties of UHPC[J]. Cement and Concrete Composites, 2021, 118: 103967.

5. Liu Y, Wei Y. Internal curing efficiency and key properties of UHPC influenced by dry or prewetted calcined bauxite aggregate with different particle size[J]. Construction and Building Materials, 2021, 312: 125406.

6. Liu Y, Wei Y. Abrasion resistance of ultra-high performance concrete with coarse aggregate[J]. Materials and Structures, 2021, 54: 1-18.

7. Liu Y, Schindler A K. Finite-element modeling of early-age concrete behavior under high level of tensile stress[J]. Materials and Structures, 2019, 52(2): 30.

8. Liu Y, Wei Y. Internal curing by porous calcined bauxite aggregate in ultrahigh-performance concrete[J]. Journal of Materials in Civil Engineering, 2021, 33(3): 04020497.

9. Liu Y, Wei Y, Guo W. Effect of filler type, fineness, and shape on the properties of nonfibrous UHPC matrix[J]. Journal of Materials in Civil Engineering, 2021, 33(5): 04021084.

10. Liu Y, Wei Y. Drop-weight impact resistance of ultrahigh-performance concrete and the corresponding statistical analysis[J]. Journal of Materials in Civil Engineering, 2022, 34(1): 04021409.

1. Technical Standards for Highway Concrete in Extremely Cold and High-Altitude Plateau Areas, T/CECS G:T52-01-2022,China Association for Engineering Construction Standardization. Author ranking 3/17.

2. Technical Specification for Application of Manufactured Sand Cement Concrete in Slipform Paver Constructed Pavement, T/CECS G:K34-01-2024,China Association for Engineering Construction Standardization. Author ranking 3/16.

3. Liu Y, Wei Y. An Ultra-High Performance Concrete with Low Shrinkage and Low Cement Content (Invention patent, authorization number: ZL 2020112451220.8,2022.6.3).

4. Liu Y, Fan W, Ye Z. A Mechanical Response Analysis Program of Concrete Member or Structure Considering the Creep Effect [The Creep Deformation Analysis Procedure of Concrete Structure] V1.0. (Software copyright)

1. World Transport Convention (WTC), Qingdao, China, Recommended Paper Award, 2024.06.

2. World Transport Convention (WTC), Xi'an, China, Excellent Paper Award, 2021.06.

3. Annual Meeting of Transportation Research Board (TRB), Washington, USA, Best Paper Award, 2018.01.

4. Member, American Society of Civil Engineers (ASCE).

5. Secretary, Cement Pavement Subject, Division of Engineering, 3rd Division Committee of the World Transportation Convention.

6. Conference organizer committee/secretary, ASCE EMI 2025 International Conference, Beijing, American Society of Civil Engineers-The Engineering Mechanics Institute.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026